Amidst the ceaseless whirl of progress. There exists a sanctum of creation where fibers are transformed into the fabric of civilization. The spinning mill stands as a testament to the synergy of industry and innovation. Where raw material evolves into woven tapestries that clothe the world. Embark with me on a journey through this realm of spinning marvels, where fibers and ingenuity intertwine.

The Loom of Tradition and Technology: Birth of the Spinning Mill

In the heart of textile history, the saga of the spinning mill finds its origin. From ancient spindles to modern machinery, the loom weaves a tale of evolution. It’s a symphony where tradition meets technology, where the rhythmic hum of spinning frames harmonizes with the echoes of innovation.

The Dance of Fibers: From Raw Material to Thread

At the heart of the spinning mill, fibers dance in a choreography that transforms cotton, wool, and synthetics into threads of possibility. The process, alchemy of pressure and tension. Metamorphoses fluffy bales into slender strands, ready to be woven into the fabric of life.

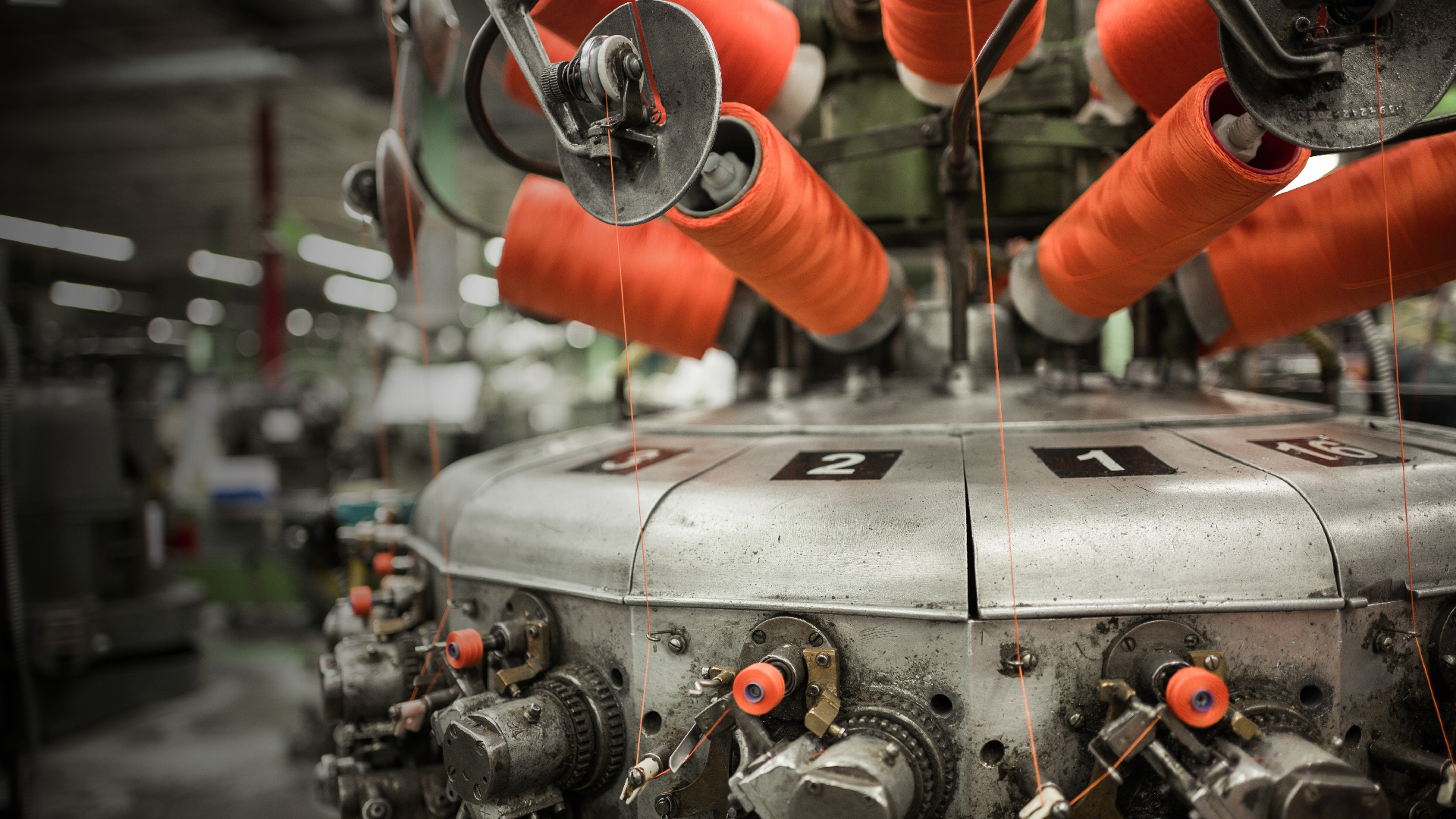

Machinery as Maestros: Spinning Wheels of Progress

As we step onto the floors of a spinning mill, we enter a symphony of machinery that transcends mere mechanics. The whirring spindles and the rhythmic bobbing of frames are the maestros conducting a ballet of precision and engineering, where every twist and turn shapes the future.

Innovation’s Textile Tapestry: The Modern Spinning Mill

In the embrace of modernity, the spinning mill isn’t confined to tradition; it’s a canvas for innovation. Advanced automation, computerized controls, and AI-driven systems synchronize with human touch, amplifying productivity and quality, and redefining the boundaries of what’s possible.

Threads of Sustainability: Weaving a Greener Tomorrow

As the world weaves new narratives of sustainability, the spinning mill isn’t a bystander; it’s a proactive weaver of change. Eco-friendly practices, energy-efficient technologies, and the use of organic fibers intertwine to create a textile tapestry that’s gentle on the Earth.

Conclusion

In the realm of the spinning mill, threads don’t just bind fabrics; they bind aspirations. Ralph Waldo Emerson’s words resonate: “Do not follow where the path may lead. Go, instead, where there is no path, and leave a trail.” The spinning mill leaves trails of innovation, weaving dreams into tangible forms that drape us in comfort, style, and the essence of progress.

Frequently Asked Questions

Q1: What is the history of spinning mills?

Spinning mills trace their history back to the Industrial Revolution. When manual spinning methods were mechanized. The transition from hand-spinning to machine-driven spinning marked a pivotal moment in the textile industry’s evolution.

Q2: How does automation impact spinning mills?

Automation revolutionizes spinning mills by enhancing efficiency, consistency, and productivity. Advanced machinery and robotic systems optimize processes, reduce manual labor, and improve yarn quality.

Q3: What role does sustainability play in modern spinning mills?

Sustainability is a cornerstone of modern spinning mills. By adopting eco-friendly practices, using organic and sustainable fibers, and implementing energy-efficient technologies, mills contribute to a greener textile industry.

Q4: What are the challenges faced by spinning mills today?

Spinning mills encounter challenges such as fluctuating raw material prices. Maintaining quality standards, adapting to market demands, and balancing traditional craftsmanship with technological advancements.

Q5: How do spinning mills contribute to the global textile industry?

Spinning mills serve as the foundation of the textile supply chain, producing yarns that are essential for various downstream processes, including weaving, knitting, and fabric production.